Preventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Applications

InfraMation 2015 Application Paper Submission

Brian Peyres

Sr. High Voltage Reliability Engineer, EDP Renewables

ABSTRACT

Dead break elbow terminations are commonly used in many wind farm and utility applications. When constructed properly, dead breaks also known as “T-Body’s” can be very reliable. Failures of this type of termination can be very dangerous and costly with regards to adjacent equipment damage and service interruptions. What are some of the causes of failure? How can we prevent failure? How do we interpret an observed anomaly?

INTRODUCTION

This article will familiarize you with dread break elbow construction and its applications. Wind farms have been increasing in number globally in the last decade, therefore a large number of transformers, junction boxes and isolation switches have been constructed using dead break elbows. Unfortunately some components have been made with lower standards to meet the recent demands. In addition to supply concerns, lack of experience by installers has resulted in costly failures for many owners. The goal of this paper is to share valuable lessons learned and provide insight on how to prevent possible failures.

FAILURES

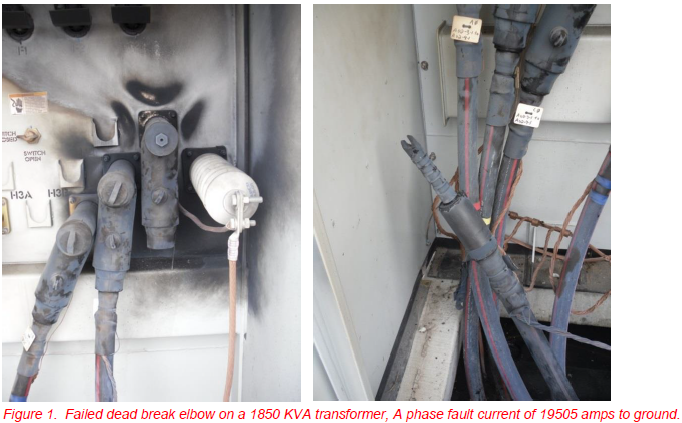

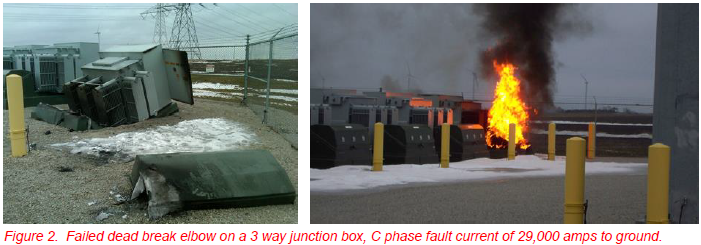

Figure 1 is an example of a failed dead break connection. This type of failure is a common occurrence when construction of a dead break elbow is not conducted properly. Damage in this example resulted in losing 25MW of possible generation for roughly 15 hours

ROOT CAUSE OF FAILURES

Reason #1 Craftsmanship

Poor assembly techniques are the primary reason dead break connections fail. Inexperience, failure to follow manufactures instructions and working with heavy cable that is difficult to form can all lead to termination failures.

ROOT CAUSE OF FAILURES

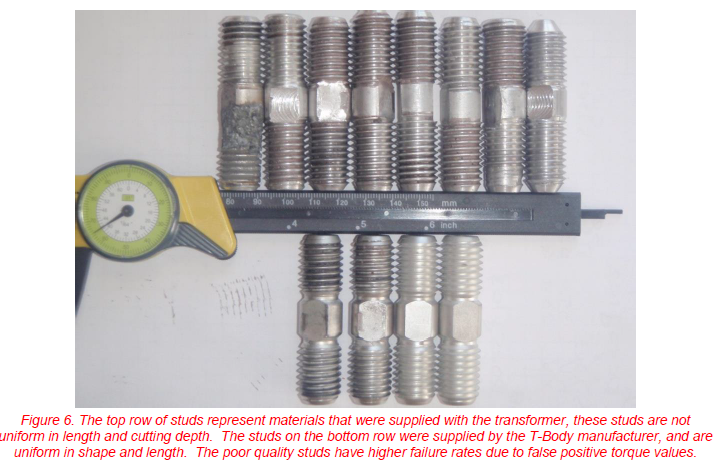

Reason #2 Material defects

ROOT CAUSE OF FAILURES

Reason #3 Environmental Stresses

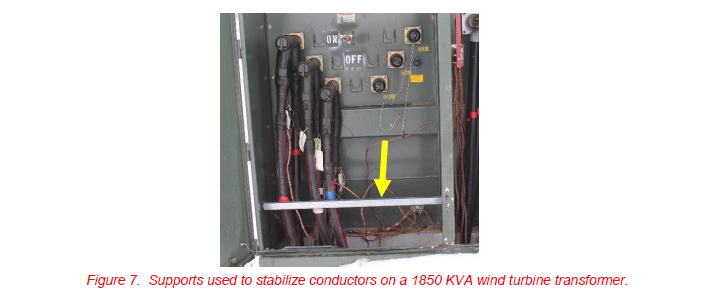

Thermal cycling of transformers can stress termination integrity due to expansion, contraction, and movement of materials. Cables can be weighed down by heavy ice that accumulates in the dead space below termination cabinets resulting in stresses on the cable. Frost heaving of equipment in winter months can also play a role in cable movement resulting in potential failure.

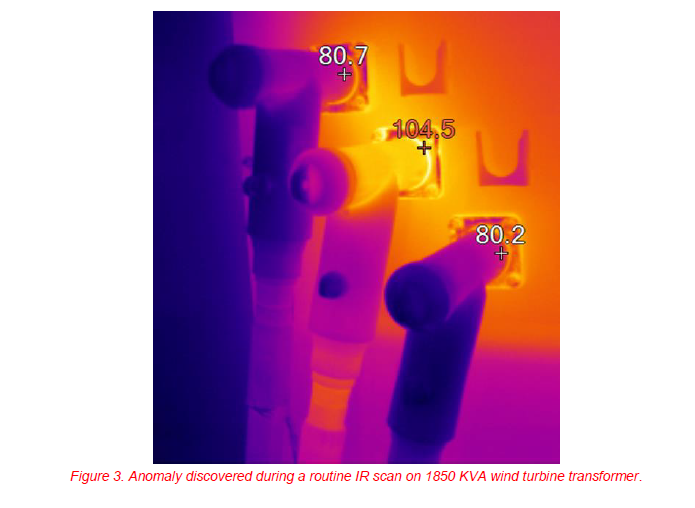

CASE STUDY

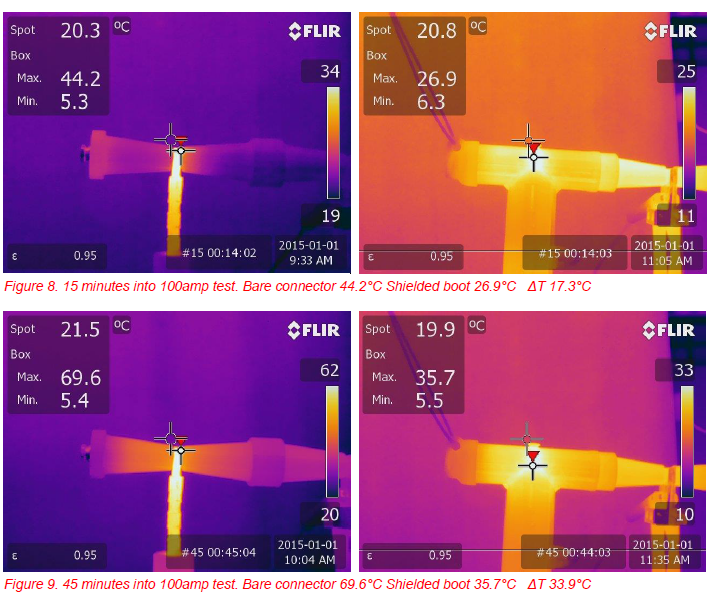

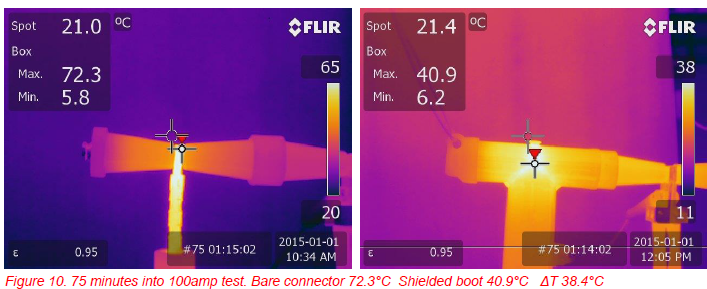

The dead break elbow is a fully submersible component with heavy shielding material that protects the termination. The design makes it difficult to see or determine if a potential problem exist. Determining the cause of an anomaly is impossible without disassembly of the elbow. The following case study illustrates differences between exposed and covered terminations with a termination defect. In the first series of tests, a termination was intentionally damaged, measured for connection resistance and subjected to 100 amps of current for a period of 75 minutes. IR images were captured illustrating the results of the high resistance connection. The second series of images illustrates the same termination with the shielding boot installed to demonstrate the heating pattern and delta between the two areas. Bushings installed in oil filled transformers may act as a heat sink resulting in a wider Delta T between the actual fault location and the observed temperature.

Note: The bare aluminum lug was painted with high temperature flat black paint allowing similar emissivity settings between the two images.

SUMMARY

IR imaging is a key tool in the prevention of dead break elbow failures when used on a routine basis. Workers should understand the mechanics of constructing this type of termination and be mindful of the small details that should not be overlooked. The case study should provide the user a good insight to the heat losses typically seen in a dead break elbow when an anomaly is discovered.

ACKNOWLEDGEMENTS

The author would like to thank the fellow employees at EDP Renewables for their hard work in the early years before IR maintenance came to existence as they suffered through many long days and nights dealing with equipment failures and for providing several of the images in this manuscript. Thanks also goes to the Infrared Training Center at FLIR Systems for their excellent instruction and EDP Renewables for providing the equipment and resources necessary to conduct the case study. A final thanks to my colleagues for their assistance and attention to detail allowing this paper to be possible.

ABOUT THE AUTHOR

Brian is a Level II thermographer with 19 years’ experience in the high voltage industry. In 2009 Brian began working in the wind industry as a high voltage reliability engineer; his infrared experience played a major role in the identification and prevention of costly equipment failures.